Epoxy-Al2O3 nanocomposites with enhanced Tg and thermal stability

Abstract

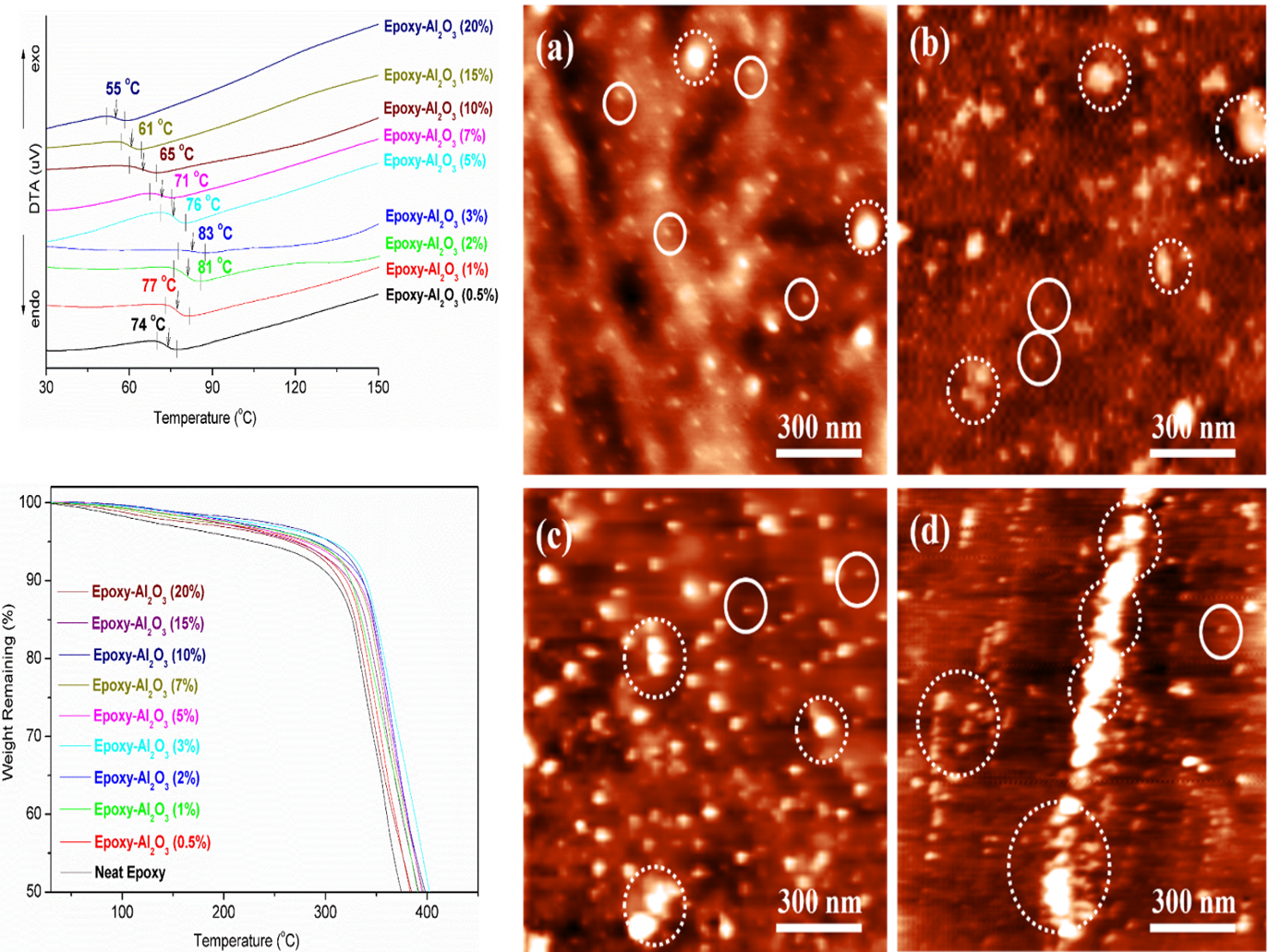

An extensive range of nanoparticle loadings, between 0.5 wt% to 20 wt%, were investigated in detail for assessing the thermal stability of epoxy-Al2O3 nanocomposites. Alumina nanoparticles were distributed uniformly throughout the viscous epoxy system with the assistance of an optimized ultrasonic dual-mixing method. The influence of nanoparticle cluster size and interparticle distance on the glass transition temperature (Tg) and thermal stability of the nanocomposites was examined in this study. Nanoparticle dispersion in epoxy was characterized using atomic force microscopy (AFM). Thermogravimetric analysis was utilized to investigate the thermal stability of nanocomposites, while differential thermal analysis was employed to estimate Tg. It was discovered that a key threshold loading concentration of nanoparticles such as 3 wt% in epoxy was found responsible for significant increase in Tg as well as the thermal stability. This type of improvements is ascribed to the advancement of a strong epoxy-nanoparticle interface, which is facilitated by dispersion of nanoparticles uniformly which limits motion of epoxy polymer chains. Moreover, the nanoparticles serve as thermal insulators, preventing flow of heat through the matrix.